How Do Air Suspended Vehicles Actually Work? An Overview for Those in a Mechanic Program

A car without need of suspension? That might sound strange if you’re unaware of the notion—but it’s more doable than you think! While traditional suspension systems help keep cars safe, supported, and under control, air suspensions are a surprisingly viable alternative for car owners. Although they are more expensive than the typical kinds of materials used for suspension systems, they also come with a host of benefits that can improve a car owner’s driving experience.

Air suspension can do what other types of vehicle suspension materials can do, but with rubber-based bags doing the work in place of plastic or metal. Here’s a rundown of how air suspended vehicles function.

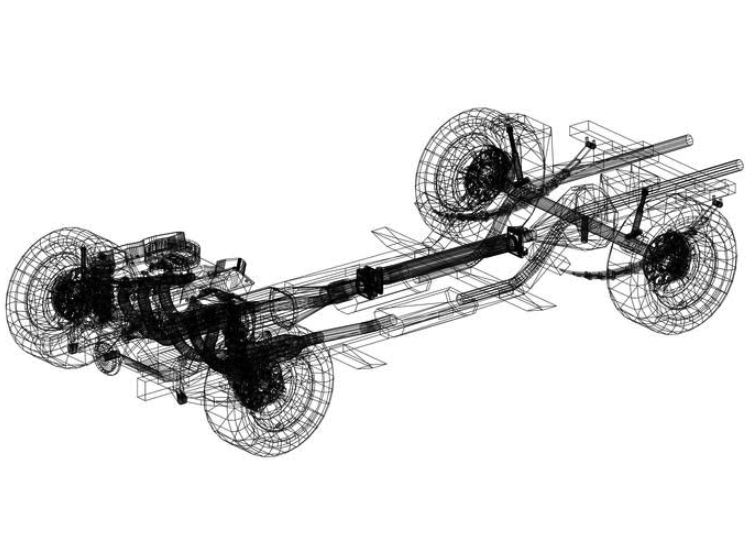

What Air Suspended Vehicles Are, and How They Work in Motion

For these types of suspensions, air springs replace the more traditional leaf or metal coil varieties. Air springs are also made from rubber, and look more like balloon-shaped bags than springs when inflated. Activating these air suspension bags can also be done by simply pressing a button. An air compressor, reservoir, and air dryer are used in conjunction with air springs at every corner to help this suspension function properly and provide the correct amount of air pressure. When functioning properly, this system allows for the ride height to be lowered. Air springs can also become stiffer the more they are compressed. An integrated air tank is used to facilitate changes in air pressure, while having the added function of helping to maintain high pressure levels.

Advantages and Disadvantages for Automotive School Students to Know About

Like most things in life, air suspensions come with their share of upsides and downsides. The less favourable aspects for students in a mechanic program to be aware of mainly concern how they can become less effective over time, with the air known to leak from these springs after long periods of usage. Installing this suspension system is also more complicated than the process is with other types. Additionally, car owners can expect to pay more for replacement springs than they would for the part on traditional systems. Air suspensions do, however, also come with various benefits. These include preventing damage to the chassis, adapting easily to weight fluctuations, maximizing fuel economy, and improving the car’s capacity for off-road activity. These springs also make it easier to climb into the vehicle, thanks to its capacity for lowering the car closer to the ground.

Additional Notes of Interest on Air Suspension

It may be of interest to students enrolled in automotive school to note that the rate of an air spring on this system can be modified at any time. This can make for a smoother, more comfortable journey for the driver. It’s also important to note that adding cargo to the vehicle can cause even further drops in ride height, with the additional weight resulting in the suspension system neutralizing the air pressure, further lowering the vehicle.

A final fact on this type of system that auto mechanics and car enthusiasts might be surprised by is that air suspensions have been around longer than people might think. A similar concept was first patented all the way back in 1901, and the air suspensions we know today were first developed for the United States military during World War II to keep trucks at an acceptable height despite heavy loads inside the vehicles.

Do you want to attend auto mechanic college?

Contact Automotive Training Centres for more information!