Want to Become an Auto Mechanic? Important Practices to Follow When Servicing Drive Lines

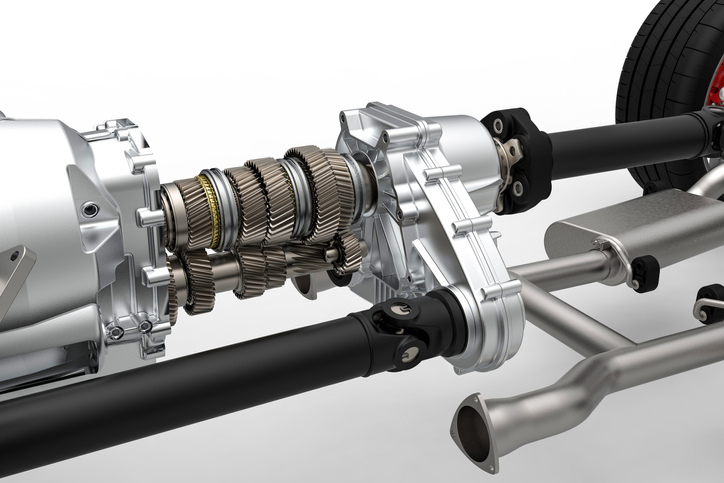

The driveline of a car takes the engine’s generated power and converts it into the rotation of the car’s tires. This conversion utilizes the vehicle’s torque and delivers speed to the car. The driveline consists of the transmission, the axles, the wheels and the driveshaft of a vehicle, and works with the engine to move the wheels. For aspiring mechanics, it is important to follow certain practices when servicing drivelines.

At the Automotive Training Centre in Toronto, you will be provided with tailored training and hands-on experience through our Automotive Technology Training Program, which will prepare you to service the drivelines and drive axles for different vehicles.

Read on to learn about some important practices you should follow when serving drivelines!

When You Become an Auto Mechanic, You’ll Know When Old Lubricants Need to be Removed

Lubricant fluid is a key component of a driveline and consists of a front and rear differential and transfer case. Eventually, over time, the fluid breaks down and becomes contaminated. When this occurs, the vehicle starts to vibrate, resist when making tight turns and make unfamiliar noises, especially at high speeds. The fluid in the front and rear differential and transfer case will then need to be flushed and replaced. When you become an auto mechanic after you complete your training at ATC Toronto, you’ll be prepared to assess when the driveline fluid needs replacing – usually after 96,560 kilometres – and how to perform the main driveline flush.

Carefully Inspect Yoke End Fittings

It’s always a good starting point to check the driveline from the transmission end of the vehicle. After your auto mechanic training, you’ll be prepared to carefully inspect issues with a driveline’s yoke end fittings, which consist of a slip yoke, a yoke shaft, a tube yoke and an end fitting yoke. You’ll check for looseness by attempting to move the yoke end fittings vertically and horizontally. You’ll also check all input and output fittings at each end of the driveshaft for looseness, and ensure all mounting hardware is in tact. If you notice movement when inspecting the slip joint yoke then it should be replaced, as movement is a sign of wear and tear in the splines of the slip joint.

Inspect Universal Joints for Any Independent Rotational Movement

When serving a driveline, you will also have to diagnose the condition of the universal joint ends. With the expertise you gain in the field as an auto mechanic, you’ll be able to assess the condition of the universal joint ends by hand. When you run this check, you’ll be able to feel for any independent rotational movement as you apply hand pressure.

If that is the case, then the universal joint ends should be tightened or replaced. You’ll also need to verify that all bearing cup assembly caps are in place, and ensure that the universal joint bolts are not missing, loose or broken.

Interested in earning an auto mechanic certification?

Start your training at ATC Toronto!