Factory Fresh: What Students in Mechanic Colleges Need to Know About New Car Development

New cars are released or updated every year. They offer new technologies, new design flourishes, and other important modifications and upgrades that are meant to entice drivers to make the leap to something new.

The process for getting new cars to market is an interesting one, with many important steps that turn concept into eventual reality. Want a peek behind the curtain? Here’s a brief explanation of how new cars are developed.

All the Cars You See on the Road Are the Product of a Lot of Research

Cars are complicated things to get to market. They need to be economical, so that the manufacturer can make a profit from their sale. They need to pass a number of safety tests, to ensure people can drive them safely. They also need to include the looks and functionality that drivers want.

To ensure a car will hit all of these marks, a great deal of research is completed to determine how the car should be designed. Often, an existing model will be used as a starting point, with research conducted into making the new car an improvement over the older one, rather than something completely new. When an entirely new car is being developed, part of the research process will include figuring out targets for things like fuel economy, pricing, and other details that need to be ironed out.

Students in Auto Mechanic Training May Know Actual Car Designs Are Pretty Similar

When you get down to it, most cars look a lot like most other cars. In part, it’s because regulations for safety and performance don’t leave a ton of room for creativity. A car with a very unique look might not perform safely in a collision, or might have too much wind resistance when driving, thus preventing it from meeting fuel economy standards. The highest-end models you see after your auto mechanic training have a bit more liberty to be unique. However, those eye-catching and effective designs almost always come with a high price tag.

Where possible, creating an interesting physical design does remain an important part of car development, with sleek lines and lengthy hoods acting as important design elements that help make cars look stylish. Designing for these kinds of qualities is a delicate balance between preserving economical function while still making a particular car recognizable.

Modeling & Testing Helps Iron Out Issues in the Cars You’ll Work On After Mechanic Training

It will be no surprise to students at mechanic colleges that drawings are just a starting point. Once a preliminary design is decided upon, a physical model of the vehicle is created to get a feel for what the car will look like, inside and out. It’s common for multiple variants of a design to be modeled together, with only one eventually chosen for final construction.

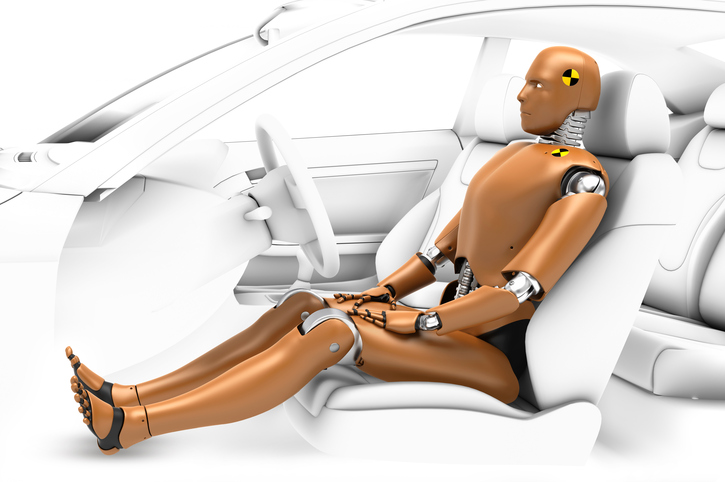

This stage of the process will be used both for reviewing the way a car looks at its proper size, and for some of the aesthetic choices that will be most visible, such as paint choices, fabrics, accessories, and more. Final testing for material choices and design effectiveness is then performed on units created from the models, ensuring that the cars deliver the safety and performance that they are supposed to. And that’s it!

It’s a lot of work, with much planning, testing, and re-testing involved, but the results today are impressive. Cars are safer than ever, and can last a long time. The average cars you will work on will often be better than great cars from decades past.

An auto mechanic apprenticeship in Cambridge is a great way to prepare for exciting careers.

Sign up for training at Automotive Training Centres today!