San Francisco-based company Divergent Microfactories (DM) has recently produced the first chassis made entirely with a 3D printer for a supercar known as the “Blade”. As you would expect from a supercar, the Blade is ridiculously fast. This is partly because the 3D printed chassis weighs 90% less than that of an average car—but also because the engine produces a whopping 700hp.

Read on to find out more about the company that hopes to bring 3D printing into the auto manufacturing market, as well as to find out the specs of the all-new Blade!

Could 3D Printing Revolutionize the Automotive Industry?

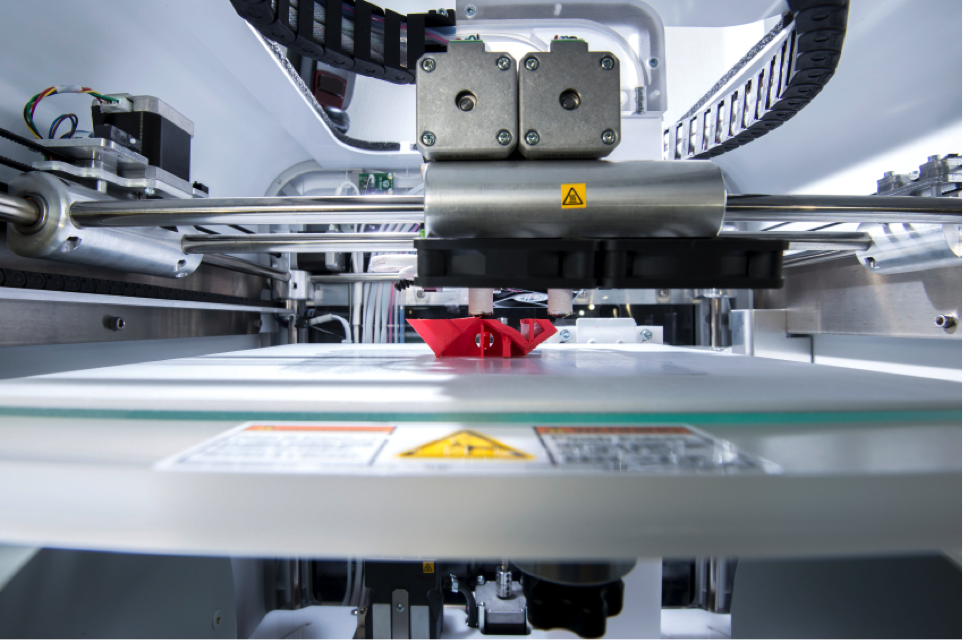

With 3D printing, manufacturers can create lighter, stronger parts at a fraction of the cost of traditional production methods. It’s a much faster way to build, too. GE has already built a mini jet engine that could change the aeronautics industry, using 3D printing technology that melts metal powder layer upon layer. This manufacturing process makes perfect sense for the automotive world as well, especially to companies like Divergent Microfactories.

For one, the Blade’s chassis is unique. Rather than building it as an entire unit, DM developed a 3D printed “Node” joint, made from aluminum. They printed carbon fiber tubes that connect these nodes, to form a very lightweight frame for the vehicle.

What would the auto service and repair industry be like if 3D printing became common? If this technology really takes off, it might one day be taught in mechanic colleges. Technicians would be able to hit a switch and build a part right in the shop, rather than having to wait days or weeks for a part to be shipped in.

A Greener Automotive Manufacturing Process

If you’re an aspiring automotive service advisor who scans car news from time to time, you’re aware that many carmakers are contributing to a greener planet by producing vehicles with less harmful emissions. DM, however, has taken things a step further.

“A far greater percentage of a car’s total emissions come from the materials and energy required to manufacture it,” explained DM founder and CEO Kevin Czinger: “How we make cars is actually a much bigger problem than how we fuel our cars.”

The company will produce a limited number of Blade supercars, but their main goal is to franchise their 3D printing technology for use by smaller manufacturers.

The Blade Supercar’s Automotive Specs

Even though 3D printing isn’t part of a standard auto mechanic course just yet, the results that DM in San Francisco came up with are incredible.

With its printed chassis made mostly out of carbon fiber, the Blade weighs-in at a total 1,400 pounds. Its 700hp engine is capable of going 0-60mph in 2.2 seconds. The Blade can also run on regular or compressed natural gas, which makes it one of the most eco-friendly supercars around.

Take a look at the Blade supercar and meet the DM team here:

What do you think we’ll see next from 3D automotive printing?