Hybrid Technology Students: How Mazda’s EV Battery Plan Could Shape the Future

Mazda, long known for its precision engineering and driver-focused vehicles, is entering the hybrid technology era in earnest. For hybrid technology students, understanding Mazda’s approach to EV batteries offers a fascinating glimpse into how a legacy automaker adapts to the growing demand for electrified powertrains.

Mazda’s electrification strategy is ambitious and innovative. It includes developing a scalable EV platform expected to debut around 2027 and establishing a battery module manufacturing plant in Japan.

Mazda’s Commitment to EV Battery Innovation

Mazda has made significant strides toward electrification. While it has already introduced the MX-30, its first all-electric vehicle, the automaker is now laying the groundwork for a broader EV lineup.

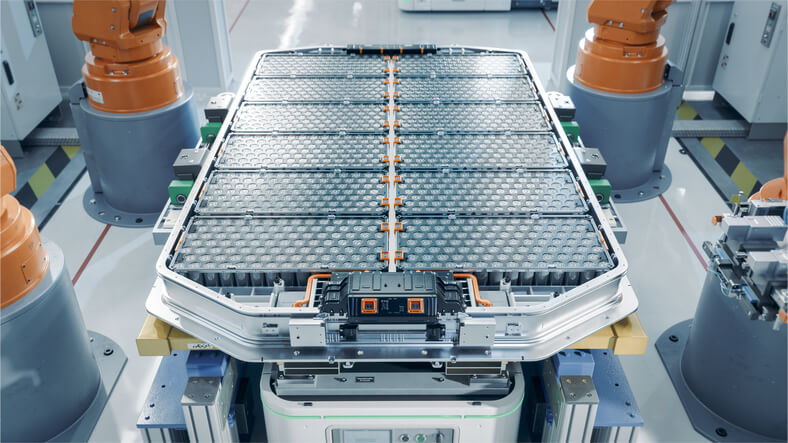

This includes the construction of a newly announced battery module manufacturing plant in Iwakuni City, Japan. The facility will assemble cylindrical battery modules using cells sourced from Panasonic, supporting Mazda’s scalable EV platform.

By partnering with Panasonic and investing in battery module production, Mazda aims to ensure its EV components’ quality, efficiency, and performance while gaining greater control over its electrification strategy.

Key Features of Mazda’s Upcoming EV Battery Technology

Although specific technical details have not yet been released, Mazda’s battery modules are expected to integrate efficiently with its evolving hybrid and EV lineup, supporting enhanced performance and energy management.

What This Means for Students in Hybrid Technology Programs

Understanding the latest trends in battery innovation is vital for students in hybrid and electric mechanic training programs. Mazda’s strategy highlights several key considerations:

- Focus on Efficiency and Range:

Mazda’s investment in battery module assembly and energy-efficient technology underscores the industry’s push for longer driving ranges and improved power efficiency. For students, these advancements represent their challenges as technicians and the opportunities to specialize in cutting-edge EV battery technologies. - Integration of Manufacturing and Design:

Mazda’s investment in battery module assembly highlights a growing trend toward vertical integration in the auto industry. For students, understanding the entire lifecycle of EV components—from design and production to installation and maintenance—will be essential as automakers shift away from third-party suppliers. - Shaping the EV Future:

The plan also focuses on advancing EV technology, including battery innovation and systems development, to support electrification.

For students, this means preparing to work in an industry that increasingly demands expertise in vehicle diagnostics, software updates, and electrical troubleshooting—skills rapidly becoming standard in hybrid and electric vehicles.

A Promising Future for Hybrid Technology Graduates

As Mazda moves toward a more electrified lineup, hybrid technology students have much to gain by studying the company’s evolving approach. With its dedicated EV platform in progress and its commitment to innovative battery solutions, Mazda is positioning itself as a serious contender in the EV space.

Students who understand these emerging technologies and their implications for vehicles and the broader auto industry will be well-prepared to contribute to this rapidly changing field. The future of hybrid technology—and the role of skilled professionals —has never been brighter.

Do you want to be a hybrid and electric vehicle mechanic?

Contact ATC Surrey for more information.