If you’ve ever wondered what gearbox an automatic transmission vehicle is equipped with, it’s most likely a planetary gearbox. Named for the manner in which the gears rotate around each other, planetary gearboxes have been around for thousands of years. Today, they can be found in most modern automatic transmission vehicles. These gearboxes are not only efficient, but also extremely durable. If you’re considering a career in the automotive industry, it’s likely that you’ll be working to repair and assess the status of planetary gearboxes. Thus, understanding their principles of operation will enhance your ability to work on automatic vehicles. Below, discover more about the history of planetary gearboxes, how they operate, and what they’re used for today.

The History of Planetary Gearboxes Explained for Those in Automotive Careers

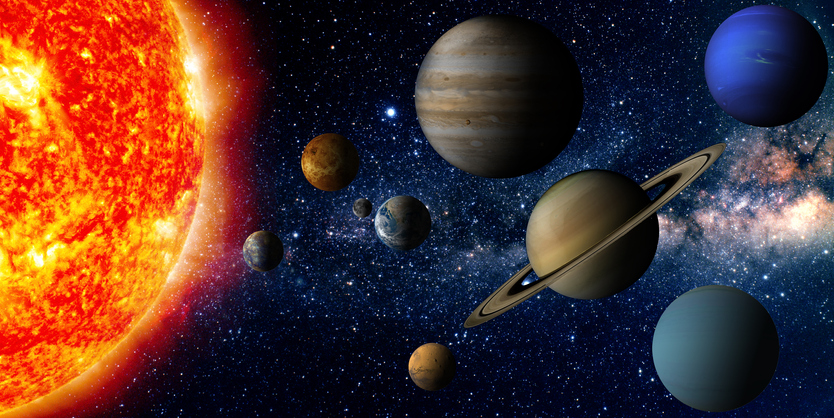

The concept behind the gearboxes found in today’s vehicles actually comes from a planetary gearbox invented over 2,000 years ago by the Greeks. True to their namesake, these components were originally developed as a means to indicate how the planets in the solar system would move. These gearboxes were developed with the use of a central drive gear, representing the Sun, around which other gears orbit. The orbiting gears are intended to represent the planets which move around the Sun, and the entire mechanism is surrounded by a ring gear. Over time, planetary gears were adapted for use in vehicles, with the Wilson-Pilcher automobile being the first to use the gearbox in the early 1900s. Later, the Ford Model T began to use these planetary gears in its two-speed manual gearbox, and the rest is history. Today, professionals in automotive careers can find planetary gearboxes used in most automatic transmissions.

How Planetary Gears Operate

Planetary gearboxes are made up of three main components, including the central gear (or the Sun gear), the multiple gears which orbit around the Sun (the planet gears), and the outer gear (also known as the ring gear). The central gear receives an input that is both low-torque and high-speed, and distributes its load to the gears around it. In turn, the distribution of the torque catalyzes the rotation of these external gears, creating an increase in torque. A carrier then connects these gears to the output shaft. The efficient transmission of torque enabled by the operation of the planetary gearbox makes them great for shifting between low and high gear ranges. For this reason, most manufacturers believe these gearboxes to be ideal for automatic transmission vehicles.

Where Planetary Gearboxes Are Used

The efficiency, durability, and high torque density of planetary gearboxes makes them perfect for use in a number of different engines. During your auto mechanic apprenticeship, you may encounter these gearboxes within internal combustion engines, hydraulic motors, and even electric motors. Planetary gearboxes can also be used in other equipment. They’re found in industrial machinery, the drive systems in aircraft and helicopter engines, and even wind turbines. Given their versatility, getting familiar with planetary gearboxes before launching your career in the auto industry will be a great way to enhance your success on the job.

Are you exploring opportunities for training in automotive industry?

Gear up for a rewarding career with a program at ATC Surrey!