As far back as the 1800s, inventors have been working on different ways to get automobiles to stop safely. While brakes have become more sophisticated over the years, the mission to protect drivers, pedestrians, and other road users has always been the same. Some mechanics have always held a fascination with braking systems, whether it is because of their ability to stop heavy machines at high speeds, or their ability to make cars safer.

Are you considering becoming an auto mechanic and want to get a head start learning more about brakes and braking systems? Here’s a brief history that shows just how far braking systems have come!

Brakes Started With Blocks of Wood and Mechanical Drums

Brakes and braking systems have really come a long way from their timber roots in the 19th century, when developing a car’s stopping power had just begun. Initially, braking systems were composed of large wooden blocks placed near the wheels, and were controlled by a lever. However, this early braking system could be found on any vehicle with steel rimmed wheels, such as early steam powered automobiles and horse-drawn carriages. When the driver pulled the lever, the wooden blocks would press against the steel rimmed wheels and bring the vehicle to a stop.

Everything changed the day the Michelin brothers started to swap out steel rimmed wheels for rubber in the 1890s. Wooden blocks alone didn’t do the trick when stopping rubber wheels, so a mechanical drum braking system was implemented instead. Designed and developed by Mr. Louis Renault in 1902, drum braking systems still involved the use of wood blocks, but added a cable wrapped around a drum that made braking easier. In many cases, Renault’s braking design was considered the first legitimate example of a modern braking system!

Grads With Mechanic Training Know All About Hydraulic and Disc Brakes

Hydraulic braking systems came first when Malcolm Loughead created them in 1918 to provide stopping power for all four wheels. Hydraulic brakes work by sending fluid whenever a brake pedal is pressed to activate the pistons and bring the vehicle to a stop. This proved to be an effective braking system during the 1920s, but it just couldn’t compensate for heat. That’s when the old familiar brake disc system came about.

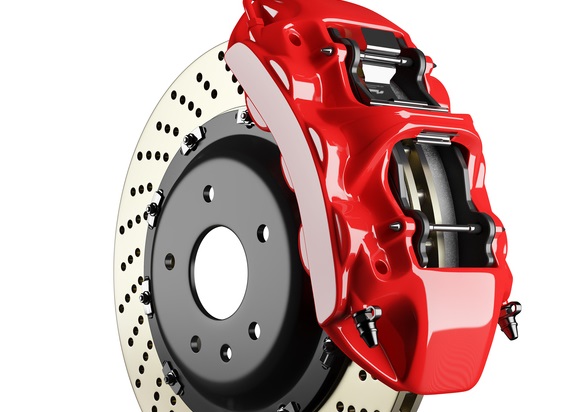

Almost all professionals with careers in the auto industry know about rotors and piston calipers, given how common it is to find them on cars today. First fitted onto cars by Chrysler, disc brakes were used in tandem with a pedal, brake shoe, and hydraulic system. When the driver needed to stop the car they merely pressed down on the pedal, causing the calipers to clamp down on the brake discs.

Anti-Lock Braking Systems Offered Greater Stopping Power When Slipping

Dreaded skids, slips, and unintended drifts are recipes for disaster unless a driver can somehow pump their brakes fast enough to bring their car to a complete stop. Pumping the brakes rapidly is something drivers used to do whenever their car slid on ice. Fortunately, new advances in technology have made this stressful safety measure less pressing than it used to be.

Anti-Lock braking systems (ABS) eliminated the need for those kinds of measures by stopping and applying the brakes several times per second. Anti-lock braking systems work by placing sensors on each of the vehicle’s wheels, so what when the wheels begin to lock up and slip, the ABS kicks in and stops the car. Brakes have only grown more sophisticated now, with collision detection and other technologies that can now activate a car’s brakes to avoid accidents. With mechanic training, you could get the chance to work on these new and fascinating braking systems!

Looking for auto mechanic certification in Toronto?

Join Automotive Training Centres now!