If your vehicle’s steering functionality glitches, your battery begins rapidly losing charge, and a disconcerting sound comes out of your engine, your car’s serpentine belt is possibly the culprit.

Although the process of replacing a serpentine belt is on the easier end of the car repair spectrum, it’s not something the average car owner would dare do themselves, given the difficulty in replicating the belt’s exact path on its complex pully structure.

For aspiring auto technicians, however, it can be a great project. Once you follow the steps and know the safety checks, you’ll be able to replace serpentine belts with ease. Interested in learning how? Read on!

Getting the Car Replacement-Ready

Replacing a serpentine belt isn’t as simple as taking the old one out and putting the new one in. There are a series of steps those in auto careers must complete before they even lift the hood.

First, park the vehicle on a flat surface, turn the engine off, and put the parking brake on. Then grab your trusty gloves and protective goggles. Now, you’re ready to get started.

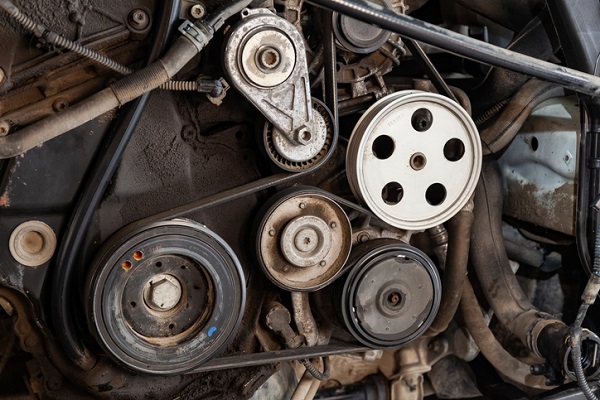

Remove any engine covers, shrouds, or plastic guards so you can clearly see the pully system which the serpentine belt runs through, and take a photo or draw a diagram of it. You’ll thank us for this tip when you go to install the new belt!

Use Your Automotive Industry Training to Install a New Belt

The process of replacing the serpentine belt starts with releasing the tensioner and removing the old belt. Quick tip: if you have difficulties in identifying the tensioner, look for the part that looks more like a smooth roller than a pully.

At this point, you can take the opportunity to check some other engine components to make sure they’re functioning properly. Try spinning the tensioner – if it’s loose or noisy, you’ll likely have to replace it, too. You may also want to test the water and smog pumps, idler pulleys, alternator, and A/C compression to make sure there are no issues. If you notice that dirt and grime is building up on the pulleys, use a wire brush to clean the grooves. This will help the new belt function better.

Now you’re ready to install the new serpentine belt. Follow the picture or diagram you created earlier and line up the belt ribs in the pulley grooves. Ensure the belt doesn’t get twisted in the process. When you’ve finished, tighten the tensioner to secure the belt.

Pros in Auto Careers Will Always Test the Belt Before Use

If you’ve completed any training in automotive industry processes, you’ll know that it’s important to always test a vehicle after completing a task to ensure that everything’s as it should be.

After installing a new serpentine belt, start the car and let it idle for a couple of minutes. When the time has elapsed, open the car hood again and make sure that the tensioner arm is sitting between the two high and low marks. If this isn’t the case, then grab a torque wrench and adjust the belt tightness until it is. Once you’ve completed your inspection, the car will be ready to hit the road!

Contact Automotive Training Centres today to discover all you need to know!