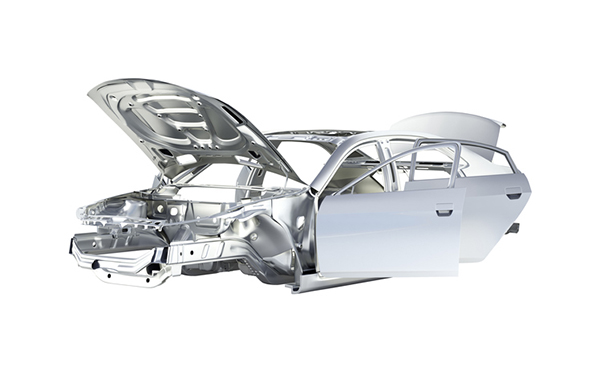

Aluminum is a strong and light metal that has been common in the aerospace industry for a long time. Over the last several decades, it has started to appear with greater frequency in cars, and with good reason. The automotive industry first saw a rise in aluminum’s popularity among race car drivers in the mid 1960s. And then, in 1994, Audi released its A8 model made entirely out of aluminum. Its weight was reduced by about a quarter of a ton because of aluminum’s lightness.

Lightness can be an especially important consideration, especially for larger vehicles such as pickup trucks. Ford knows this, and recently switched its entire F series to aluminum. This rise in aluminum needs to be heeded by anyone working in auto body repair. To find out why, keep reading.

A Career in Auto Body Repair May Find You Encountering More Aluminum in the Future

In the automotive world, weight matters. This is especially true when it comes to fuel efficiency. According to Excel Collision Centers, using aluminum just for the internal components of an average mid-size car can make it 24 per cent lighter, resulting in a fuel consumption reduction of over one litre of fuel every 100km. Taking this into account, higher gas prices and moves to reduce carbon emissions are making aluminum a more attractive metal for car owners and manufacturers. In fact, it has been speculated that aluminum could be the number one metal for use in the construction of cars in the future. As such, anyone with a career in auto body repair could see an increased demand for working with aluminum in the years to come.

Special Skills Are Required to Fix Up an Aluminum Body

Graduates of auto body training know that aluminum and steel are very different from each other. Fixing up aluminum is different than working with steel, and not following certain rules could lead to serious damage done to the metal. For starters, aluminum doesn’t have metal memory like steel does, so it can’t be reshaped as easily into its original form. Instead, aluminum needs to be heated and smoothed out. However, it conducts heat more than steel does, so welding can be a messy business if done improperly. Special welding tools are needed to do the job right. Typically, aluminum panels are replaced entirely and bonded and riveted into place, again using special tools.

Clients Will Most Likely Seek Out Auto Body Repair Shops Certified to Fix Aluminum

Clients seeking repairs may often look for shops that are certified to work on an aluminum body, since using tools such as an aluminum dent pulling station requires specialized training. It’s not only the tools and knowledge required for certification that are specific, but also the spaces in which auto body work is completed. This is because steel and aluminum corrode each other. Repairs of each metal cannot be done in the same space, because even steel dust can corrode aluminum if the two come into contact. Businesses seeking to work on cars made of aluminum must take all of this into account to keep pace with this ever-evolving industry.

Are you looking to be at the forefront of repairs on the next generation of cars?

Explore what Automotive Training Centres’ auto body repair courses have to offer!