What are Planetary Gear Sets? A Guide for Hybrid and Electrical Mechanic Training Students

An essential component of most modern gearboxes, planetary gear systems (also known as epicyclic gear systems) are a fascinating and unique feat of engineering. Originally invented by the Greeks over 2,000 years ago, planetary gears were first used as a means of understanding the movement of planets in the solar system, hence their name.

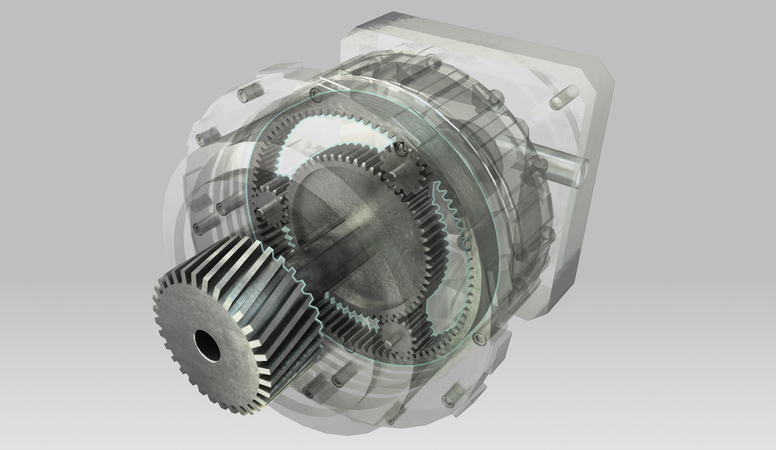

Planetary gears are modeled to mimic the movement of the planets, consisting of a “sun” gear–or a central drive gear–and “planet” gears which orbit around it with the help of a ring gear. In 1937, Oldsmobile created an automatic transmission that operated using planetary gears, and these gearboxes have been used in vehicles ever since.

If you’re considering a career as a hybrid and electric vehicle mechanic, it’s likely that you’ll encounter more than a few planetary gearboxes on the job, as these gearboxes are compatible with both electric motors and internal combustion engines and hydraulic motors. Below, learn more about planetary gears, how they operate, what kind of vehicles they’re found in and how to maintain them.

How Do Planetary Gears Work?

Planetary gears consist of a few key components, including the central gear (sun gear) which operates as the input gear and two or smaller planet gears which rotate in place alongside the sun gear. These gears are held together by a larger ring gear, and the unit is connected to a carrier, linking it to the output shaft. When the sun gear turns, the “planets” rotate accordingly, catalyzing the rotation of the output shaft in the opposite direction.

Thanks to their design, planetary gears are highly efficient and strong, enabling them to handle a high amount of torque. This makes them ideal for use in a number of different engines, including electric vehicles. As a hybrid and electric vehicle mechanic, you’re likely to see them in operation throughout your career.

What Are Planetary Gears Used for?

While they’re compatible with a number of different types of engines, planetary gearboxes are found more commonly in some transmissions than others. They are often used as the key components in the hydraulic planetary automatic transmission, the most frequently used type of automatic transmission. In fact, they’re found in most of the automatic transmissions that modern cars are equipped with today. Aside from being used in vehicles, planetary gears are also commonly found in other types of machinery and equipment, including wind turbines, helicopters, laser-cutting machines, meat slicers, operating tables and more.

Planetary Gear Maintenance Tips for the Hybrid and Electric Vehicle Mechanic

Just like all gearboxes, planetary gears require routine maintenance. After hybrid and electrical mechanic training, your knowledge of planetary gears will enable you to service all kinds of hybrid and electric vehicles that enter your shop. While these gearboxes are more durable than most, it’s important to remember that just like most automotive components, planetary gearboxes will require lubrication to prevent wear and tear. What’s more, the gears of a planetary gearbox may begin to slip over time, making routine maintenance important in identifying signs of wear and making replacements or fluid changes as necessary.

Ready to enroll in a hybrid and electric mechanic course?

Contact ATC Montreal for more information!