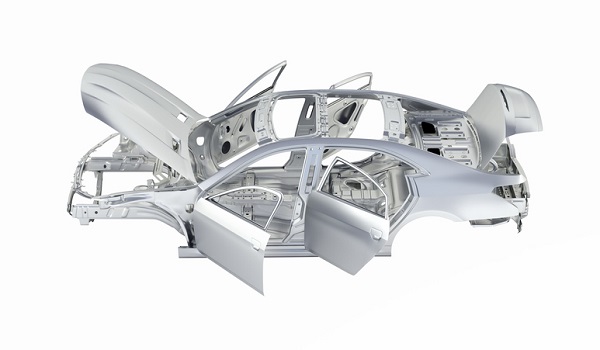

Auto body manufacturers have been looking for new ways to make cars lighter, safer, and more efficient almost since the car was first invented. As fuel economy and energy efficiency standards continue to rise, many manufacturers are turning to aluminum to create a more lightweight, resilient car body. Ford, for example, recently made the decision to incorporate aluminum into its popular F-150 model, and aluminum-intensive vehicle (AIV) bodies or multi-material vehicles (MMV) containing aluminum are becoming more and more prevalent.

This means that auto body technicians can expect to see more of this metal in the future, and knowing the right and wrong way to work with aluminum can be to your advantage when an aluminum auto body rolls into your garage.

If you’re interested in starting a career as an auto body repair technician, read on to find out what you can expect from working with aluminum.

Auto Body Pros Know Aluminum Repair Is Different from Standard Steel

For a majority of automotive manufacturing history, the go-to metal was steel, and for obvious reasons: it’s durable, cost-effective, and easily repairable. Although it won’t be immediately replaced by aluminum overnight, there are some things you should know in case you come across a car or two that does require aluminum repair.

Aluminum is more difficult to repair than steel because it doesn’t have what’s known as a “metal memory”. Metals like steel are capable of bending back into their original shape under pressure, but aluminum does not share the same properties, and instead has to be reformed, which is more labor-intensive, time-consuming, and expensive.

You will also need special tools if you work with aluminum in your career in auto body repair, because the ones which work on steel can actually damage aluminum.

How Does Aluminum Factor into Dent Repair for Auto Body Technicians?

Dent repair is an important component of your auto body training, and although you may be primarily working with steel, it’s important to know how aluminum will respond to common dent repair methods.

Due to its lack of metal memory, aluminum has to be heated in order to be reformed, smoothed out, or worked with. Aluminum is actually quite sensitive to heat because it conducts and absorbs it much faster than steel. One common mistake, for example, is setting the welding temperature too high, which can compromise the safety of the aluminum parts you’re repairing or simply burn straight through them. This means that whenever you apply heat to aluminum, you’ll need to be extra careful. Aluminum is also rarely welded, and is instead typically bonded and riveted in place.

After the dent is repaired, there are a few things you should do before applying the paint and final touches. Cosmetic corrosion can form quickly on exposed aluminum, so an aluminum-specific coating can help provide a smooth painting surface as well as extra protection against corrosion.

Are you interested in taking the next steps towards a rewarding automotive career?

Contact Automotive Training Centres for more information about our auto body schools.